Polestar has emerged as a trailblazer in the automotive industry, pushing the boundaries of what’s possible in sustainable mobility. In this interview, Fredrika Klarèn shares how Polestar’s bold climate vision—anchored by the Polestar 0 project—is reshaping the future of electric vehicles through innovation, transparency, and uncompromising design.

Fredrika, Polestar has established itself as a leader in sustainable mobility with ambitious goals like the Polestar 0 project. Could you start by giving us an overview of Polestar’s sustainability vision and the core principles guiding your work?

Polestar aims to become a fully climate-neutral company by 2040, with the Polestar 0 project at its core: the goal is to develop a truly climate-neutral car by 2030, without relying on carbon offsets. Our sustainability strategy focuses on elimination of emissions, transparency, and integrating sustainability with design and innovation – without compromising any of these elements.

The Polestar 0 project aims to create a truly climate-neutral car by 2030. What key milestones have been achieved so far, and what are the biggest technical and systemic challenges you still face?

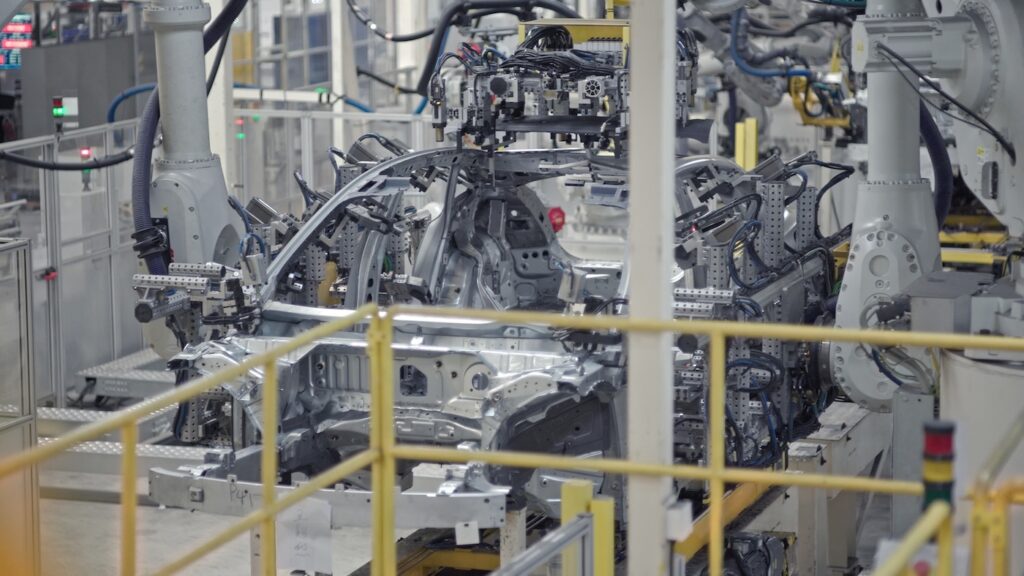

We’ve already reduced greenhouse gas emissions per vehicle sold by 25 % since 2020. Through three years of research, we’ve shown that about 10 tons of CO₂ can be eliminated from a car like the Polestar 2, primarily through innovations in steel and aluminium. Major challenges remain in finding climate-neutral solutions for electronics, plastics, and chemicals. Beyond 2030, the path to further emission cuts is still uncertain, which is why we continue to invest heavily in research and partnerships.

Polestar has embraced ‘transparency’ by publishing lifecycle assessments and revealing emissions data. How has this impacted consumer trust and industry expectations – and what have been the most challenging or rewarding aspects of implementing this approach?

Transparency has helped us build trust with consumers and encourages a more informed, critical approach to vehicle choice. Publishing life cycle assessments and emissions data empowers buyers to ask questions and demand better from the industry. The biggest challenge is collecting accurate, traceable data across complex supply chains—but the reward is real accountability and a stronger relationship with our community.

The automotive supply chain is notoriously complex. What specific strategies is Polestar using to promote ethical labour practices and environmental responsibility – and what have been the most valuable lessons learned along the way?

We identify and monitor risk materials in our supply chain and prioritize due diligence. Transparency is fundamental – achieved through supply chain mapping, certifications, and traceability tools. For high-risk materials like cobalt, lithium, nickel, and mica, we use blockchain technology to verify sourcing and ensure ethical and environmental standards are met.

You’ve partnered with companies like Bcomp, SSAB, and Norsk Hydro to innovate around sustainable materials. How do such collaborations contribute to Polestar’s mission, and how do you ensure these innovations meet performance and safety standards?

Collaborations are essential to our sustainability efforts. Working with material suppliers and research institutions helps us co-develop innovative solutions that reduce emissions while meeting high standards for safety and performance. These partnerships enable us to explore new materials and technologies, particularly in areas like metals, composites, and interior design, which are critical to lowering a vehicle’s climate impact. Not only we benefit from this, but also our partners and hopefully soon the entire industry far beyond cars.

Polestar is exploring blockchain to improve material traceability. Can you share how this technology is being used – and perhaps provide a concrete example of its application and benefits?

We use blockchain to trace battery materials like cobalt, lithium, nickel, and mica. It provides verifiable data on sourcing and allows us to take corrective action if supply chain practices fall short of our standards. This transparency ensures accountability and supports ethical sourcing at scale.

Polestar is known for sleek design and performance. How do you balance these brand-defining qualities with sustainability imperatives – especially when they occasionally conflict?

At Polestar, we believe design and sustainability complement each other. We strive to integrate both without compromise. One example is our knit upholstery: it’s visually striking, performance-oriented, and made from recycled materials with minimal waste. This material was developed collaboratively with a Swedish School of Textiles, showing how design, innovation, and sustainability can reinforce one another.

What role does battery recycling and second-life use play in your sustainability roadmap? How is Polestar building a circular system for electric vehicle components?

Battery circularity is critical. Together with Volvo, we’ve set up battery centres to explore ways to repair, remanufacture, and recycle batteries. We are also designing cars to make recycling easier. Our goal is to maximize the reuse of materials and prepare for the future when large volumes of used EV batteries return for processing. But it is also important to remember that the lifespan of a battery in a car itself already exceeds the 200,000 km mark.

What is Polestar’s current stance on e-fuels in the context of sustainable mobility – and do you foresee any role for them in your long-term strategy?

At Polestar, we’re fully committed to electrification as the most effective path toward climate-neutral mobility. While e-fuels are being explored by others in the industry, they’re not part of our core strategy. Our focus is on eliminating emissions at the source, rather than compensating for them. That said, we do look at alternative low-emission solutions in areas where electrification isn’t yet feasible. For instance, we’ve started using renewable biofuels in our ocean freight operations. It’s a practical step that fits into our broader climate roadmap.

Polestar’s LCAs have shown emission improvements in newer vehicle models. What specific changes have contributed to those gains – and how do you see this trend evolving with your next generation of cars?

Emission reductions have largely come from material improvements – especially in steel and aluminium – as well as increased recycled content and more efficient design. The focus has been on reducing production-related emissions, which is where most of a vehicle’s carbon footprint lies. We have already been able to reduce emissions from our vehicles by 25 %.

You’ve emphasized that sustainability must be embedded into the business model, not bolted on. How has this mindset influenced Polestar’s internal decision-making and corporate culture?

Sustainability isn’t treated as an add-on at Polestar – it’s one of three core pillars, alongside design and innovation. This holistic approach challenges teams across all departments but also creates synergy. It ensures that sustainability considerations are embedded in product development, supply chain decisions, and strategic direction.

Polestar has called for greater cooperation across the auto industry to reach climate targets. What steps are you taking to drive collective action, and where do you see the greatest opportunity for shared progress?

We know we can’t do this alone. That’s why we actively call for collaboration across the entire automotive industry. A great example is the Polestar 0 project, where we’re inviting partners from academia, material science, and even competing OEMs to join forces in developing truly climate-neutral materials. We’re all going to need these solutions – so it’s essential that we build them together.

To support this, we launched the Mission 0 House – a collaborative research platform designed to bring together innovators, scientists, and companies willing to contribute to this mission. It’s not just a lab; it’s an open invitation. We’re still missing partners in areas like electronics, plastics, and chemicals, and the Mission Zero House is a fantastic opportunity for them to get involved and accelerate progress.

Shared progress will come from transparency, openness, and collective innovation. We want to lead by example – and we welcome anyone who shares our vision to join us on this journey.

What role do you believe consumers play in accelerating the transition to climate-neutral mobility – and how does Polestar engage its community to foster that sense of responsibility?

Consumers are vital in accelerating the shift to climate-neutral mobility. By sharing data transparently and communicating openly, we hope to raise awareness and make buyers more selective. We want them to ask tough questions and drive demand for more sustainable vehicles – not just from us, but from the entire industry.

You previously held sustainability roles at IKEA and KappAhl. How have those experiences shaped your leadership style and your approach to driving change in the automotive industry?

My experience at IKEA and KappAhl deeply shaped my view on sustainability. At IKEA for example, I learned to embed sustainability into every business area, making it a core value. Coming to automotive from fashion, I was also very positively surprised about how recyclable a car and also a battery is. I mean, in theory, you can pick apart a car and a battery and extract so much components and materials to reuse and recycle.

Looking ahead, what emerging technologies or innovations excite you most – and what makes them especially promising for advancing Polestar’s sustainability goals?

I’m motivated by curiosity and the drive to solve problems. Sustainability is constantly evolving, and I’m excited to work with passionate colleagues at Polestar who are actively addressing the climate crisis. For example, I’ve learned that larger batteries can be better when used for energy storage, challenging old assumptions. This agility is key to advancing Polestar’s sustainability goals.

Photo/Source: Polestar